Date of issue: August 16, 2018 Author: powder technology website

Organobentonite is a kind of organobentonite complex that can replace the exchangeable cation in montmorillonite with organic ammonium cation, make it cover the surface of montmorillonite, block the adsorption center of water, make it lose the function of absorbing water, and become hydrophobic and lipophilic.

The bentonite after replacement reaction can also show excellent dispersion, expansion, adsorption, adhesion and thixotropy in organic solvents.

At present, the price of organobentonites is about 10000 yuan / T at a low price and 30000-40000 yuan / T at a high price. With the continuous progress of organobentonite production and processing technology and interest driven, more and more bentonite enterprises began to produce organobentonite.

1. How to prepare organobentonite?

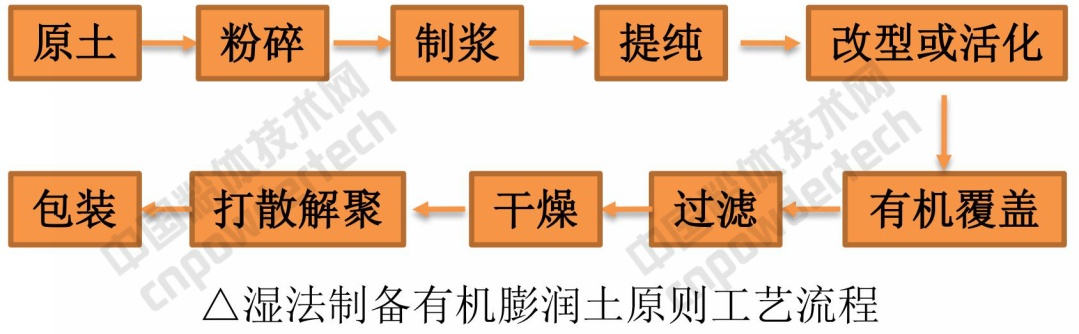

The preparation process of organo bentonite can be divided into 3 types: wet process, dry process and pre gel method.

(1) Wet process

Pulping: the bentonite is fully dispersed with water and sand particles and impurities are removed. In order to make the bentonite disperse well, it can be mixed and added dispersant at the same time.

Purification: if the purity of the original soil is not enough, it should be purified.

Modification or activation: in order to improve the cation exchange capacity of the original bentonite, the CA bentonite and Na bentonite with lower cation exchange capacity must be modified first. In order to enhance the interaction between bentonite and organic covering agent, bentonite is usually pretreated with inorganic acid or hydrogen ion exchange resin before covering.

Organic covering: heat the pulp to 38-80 ℃, add organic covering agent slowly under continuous stirring, and then continuously stir for 30-60min to make it fully react.

After the reaction, stop heating and stirring, wash and filter the suspension, dry it, disperse and depolymerize to obtain organic bentonite product.

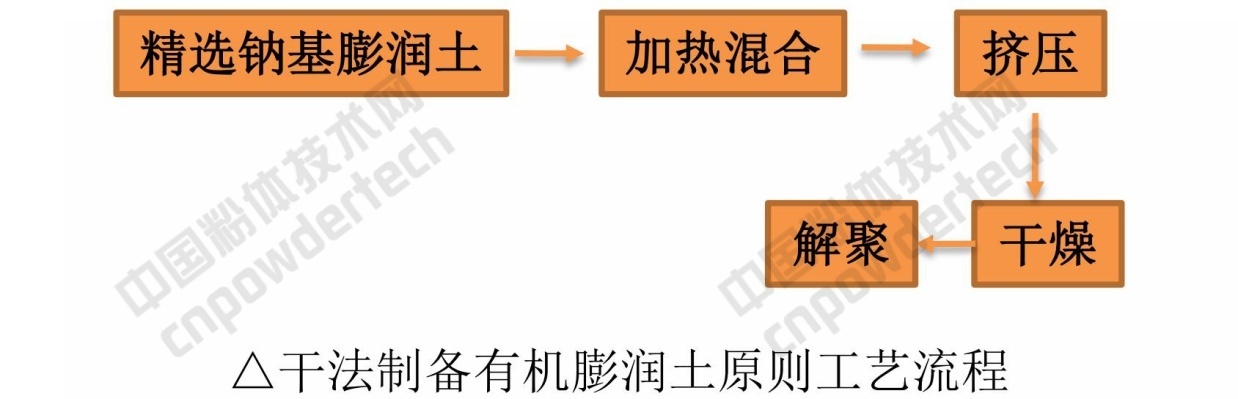

(2) Dry method

The selected sodium bentonite with 20% - 30% water content is directly mixed with organic covering agent, mixed evenly with a special heating mixer, and then extruded to produce organic bentonite with certain water content.

The hydrated organic bentonite can be further dried and dispersed to form powdery products, or it can be dispersed directly in organic solvents to produce gel or latex products.

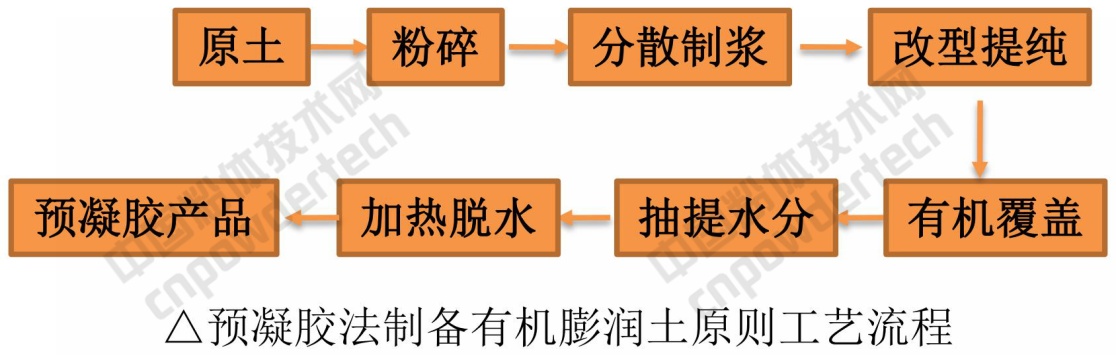

(3) pre gel method

The crushed raw soil was dispersed and pulped, modified and purified, and then covered with organic materials. In the process of organic mulching, hydrophobic organic solvents (such as mineral oil) were added to extract the hydrophobic organobentonite complex into organic phase, separate the water phase, and then remove residual moisture by evaporation, and directly prepare bentonite pregel.

(4) Factors affecting the quality of organobentonite

The main factors affecting the quality of organic bentonite are the quality of bentonite (type, purity, exchange capacity, etc.), the structure, dosage and usage of organic covering agent, and the preparation conditions (pulp concentration, reaction temperature, reaction time, etc.).

Raw materials: there are strict requirements for the raw materials used in the production of organic bentonite. The content of montmorillonite is more than 90% - 95%, the particle size is less than 2 μ m, the content is more than 95%, the interlayer exchangeable cation is mainly Na +, the interlayer charge is low, the degree of isomorphic substitution order is low, and the cation exchange capacity is more than 0.8 mmol / g.

Montmorillonite with high interlayer charge and high degree of isomorphic substitution order, such as chert montmorillonite, is not suitable for preparing organic clay.

Montmorillonite, which is between the low interlayer charge and the high interlayer charge, can also produce organic bentonite with good quality by selecting appropriate organic covering agent and preparation process.

Organic covering agent: the structure, dosage and usage of organic covering agent directly affect the quality of organic bentonite. The structure type and the length of carbon chain of organic covering agents are different, so their lipophilicity is obviously different, which directly affects the application performance and use of organobentonites. The affinity of organic ammonium salt to montmorillonite is related to its relative molecular weight. The higher the relative molecular weight is, the easier it is to be adsorbed by montmorillonite. This is because higher ammonium salt not only has exchangeable cation exchange reaction with montmorillonite, but also has molecular adsorption.

Therefore, the number of long alkyl carbon atoms of quaternary ammonium salt should be more than 12.

There are several kinds of quaternary ammonium salts commonly used in foreign countries: bis (octadecyl) ammonium salts, such as ODB dimethyl bis (octadecyl) ammonium chloride and ot trimethyl octadecyl ammonium chloride, among which bis (octadecyl) ammonium salt has the best performance.

At present, the covering agents used in our country are generally 18 carbon atom ammonium compounds such as dimethyl octadecyl ferric chloride and trimethyl octadecyl ammonium chloride. The results show that the effect of using more than two kinds of covering agents is better than that of using single covering agent in some properties and uses.

Stability and amount of covering agent: the stability of organobentonite suspension is closely related to the amount of covering agent. When the amount of covering agent is equal to the cation exchange capacity of montmorillonite, all exchangeable cations are exchanged by organic ammonium salts, and the viscosity of the suspension is the highest. If the amount of organic covering agent is increased, the viscosity of the suspension becomes smaller.

Therefore, the amount of covering agent should be appropriate to meet the principle of cation exchange capacity, too large and too small can not get the maximum viscosity value.

Pulp concentration: when preparing organic bentonite, the best pulp concentration is the full dispersion of bentonite. Too high concentration leads to the dispersion of bentonite, which affects the exchange reaction between bentonite and organic ammonium salt ions. Although too low concentration helps to disperse, it consumes a lot of water and increases the production cost. The pulp concentration is generally 5% - 7%.

Temperature: it is an important factor that affects the exchange reaction between organic ammonium cation and exchangeable cation in bentonite. Therefore, the temperature must be appropriate. Generally, the optimum temperature is about 65 ℃.

Reaction time: it is generally related to pulp concentration and reaction temperature, ranging from 0.5h to several hours. The best reaction time should be determined by experiment on the basis of other process conditions.

2. Market prospect analysis of organobentonite

Organobentonites are widely used in coatings, oil drilling, inks, fire extinguishing agents, high temperature lubricants and other fields.

(1) Paint Market

The global demand for paints and varnishes in 2014-2018 is expected to maintain a growth rate of 4.7%. In the next few years, Argentina, China, India, Morocco and the United States are considered to be the most potential Coatings Markets.

Currently, paints and varnishes based on non-aqueous polymers (except polyacetic acid, vinyl and acrylic polymers) account for 36.6% of global demand. In recent years, the rapid development of architectural decoration industry in the Asia Pacific region also promotes the growth of global green environmental protection coatings market demand.

It is predicted that the sustainable development of global building decoration industry and automobile manufacturing industry will become the main growth power of global green environmental protection coatings market in the future. The output of China's paint and coating industry is close to 10 million tons / year. According to the requirement of adding 0.3% - 2%, only the demand of the paint and coating industry for organic bentonite will reach 30000-200000 tons / year.

(2) Drilling mud market.

It is reported that China's shale oil recoverable resources are 3.7 billion tons, and China's oil exploitation will continue to strengthen. According to the demand for oil drilling mud, the average addition of 4.0 tons of organic bentonite to each well, the demand for organic bentonite in oil drilling and shale oil (gas) drilling will reach about 10000-30000 tons / year.

(3) Grease Market

At present, the main application fields of grease are metallurgical system, railway system, precision bearing, automobile industry, etc. adjusting product structure and improving product quality are the main development direction of China's grease industry, and the goal is to increase the output of high drop point grease products.

At present, China's domestic demand for lubricating grease has reached 420000 tons / year, and the demand for organic bentonite, especially nano organic bentonite, in the grease industry will reach about 10000-50000 tons / year.

In the next few years, the domestic market demand for organobentonites will reach 300000-400000 tons / year, and organobentonites will continue to develop in the direction of refinement, serialization and functionalization. The main development direction of organobentonite industry is to actively carry out the research of organobentonite production technology, speed up the industrialization transformation of achievements, expand the application field of organobentonite, and realize the comprehensive utilization of organobentonite with high efficiency and high added value.

At present, domestic organobentonite production enterprises mainly include:

Zhejiang Qinghong New Material Co., Ltd., Zhejiang Huate New Material Co., Ltd., Zhejiang Huate industrial group Huate Chemical Co., Ltd., Zhejiang Hongyu New Material Co., Ltd., Hangzhou Xihe Chemical Co., Ltd., Anji Yuhong clay Chemical Co., Ltd., Zhejiang Fenghong clay Chemical Co., Ltd., Zhejiang Anji Tianlong organic bentonite Co., Ltd., and Lin'an Qinghong additives Co., Ltd Chemical plant, Hebei Hejian Rongcheng organic bentonite plant, Fujian Hongqiang organic bentonite Co., Ltd., Zhengzhou Jiuzhou Chemical Co., Ltd., Zibo Lianji Chemical Co., Ltd.