According to relevant data of China powder.com, the total domestic paper production in 2017 was about 111.1 million tons, up 2.3% year on year. As the demand for paper and paperboard in developed countries continues to shrink, China has become the main driving force for the growth of global demand for paper and paperboard. China is expected to account for 65% of global paper and board growth from 2015 to 2020. At the same time, China's pulp demand will maintain a growth rate of 2.5%.

With the increasing scarcity of wood resources for papermaking and the improvement of people's concept of green environmental protection, more and more attention has been paid to the fillers for papermaking, which can reduce the consumption of pulp fiber and reduce the cost. In addition, fillers have the following functions in papermaking:

improve the whiteness of paper.

Increase the opacity of the paper.

improve the smoothness of paper.

improve the softness of paper.

improve the printing performance of paper.

reduce the deformation degree of paper, that is, improve the flatness and shape stability of paper.

reduce resin barrier.

meet the special requirements of some papers.

At present, the four fillers commonly used in papermaking are talc, kaolin, PCC / GCC and titanium dioxide.

How to choose paper filler reasonably?

papermaking is a complex process. Different kinds of paper have different quality requirements. In order to meet certain requirements of paper, fillers must be added. There are many kinds of fillers and their properties are also different. Therefore, different kinds of fillers or combinations of fillers must be selected to obtain the best results for different paper varieties and requirements.

Talc

(1) Talcum powder has the characteristics of fine texture, high whiteness, good coverage, high smoothness and gloss, low wear and tear, and is cheap. Talcum powder is used as filler in general cultural paper and printing paper.

(2) Due to the good chemical stability of talc powder, the acid sizing with dispersed rosin as sizing agent uses talc powder as filler.

(3) Talc powder as a white pigment has a negative effect on the whiteness of coating. According to the research, the whiteness value will decrease by 1.0% when the dosage increases by 10%. Therefore, talcum powder is not used as pigment as much as possible in the production of coated paper.

Calcium carbonate & nbsp;

(1) Calcium carbonate can be divided into heavy calcium and light calcium. For thin paper, such as cigarette paper, printing type tipping base paper, due to the requirement of high opacity, calcium carbonate is used as filler. In addition, calcium carbonate has less absorption of ultraviolet light and is more resistant to paper aging. Therefore, calcium carbonate is also used as filler for some papers that need to be preserved for a long time.

(2) The refractive index of calcium carbonate is as high as 1.65, which can significantly improve the whiteness and opacity of the paper. In the range of pH 7.5 ~ 8.5, the stability of calcium carbonate is good, so the paper with medium (alkali) sizing uses calcium carbonate as filler. The paper with acid sizing can not use calcium carbonate as filler.

(3) Calcium carbonate can be widely used as pigment for coated paper. The price of heavy calcium carbonate is cheap, the fluidity of the coating is good, and its printing performance is better than that of light calcium carbonate, so the white coating of heavy calcium carbonate is more used.

Kaolin

(1) Because of its good chemical stability and sheet structure, kaolin can improve the smoothness and glossiness of paper, so it can be used as a filler for all kinds of paper. Sometimes in the paper production process, in order to improve the opacity of the paper and improve the printing performance of the paper, part of calcined kaolin should be added in the filler.

(2) Kaolin is only suitable for the filling of acid sizing paper, but because of its high viscosity, it is usually used together with talc.

(3) Kaolin can be used as white pigment for coating. The higher the flake content of kaolin, the better the coating performance (coating fluidity), the better the glossiness and smoothness of coated paper.

Titanium dioxide & nbsp;

Titanium dioxide has high refractive index and whiteness (97% ~ 99%), and its covering power ranks the first among pigments (fillers). It can be used in the production of high-grade tissue paper or high-grade coated paper, but its price is expensive, so its consumption is small.

Common paper filler varieties and addition amount

Development trend of fillers for papermaking

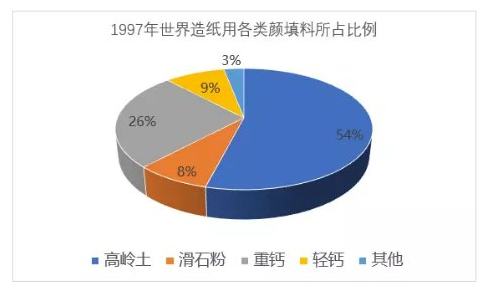

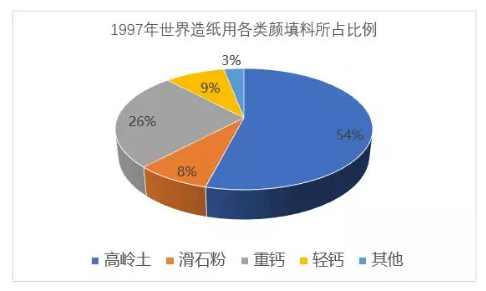

the world papermaking industry has successfully switched to alkaline and neutral papermaking processes since the early 1980s, which provides a huge application market for heavy calcium products. In the past, the most commonly used paper filler kaolin was gradually replaced by calcium carbonate. In terms of the proportion of consumption varieties, the dominant position of kaolin (more than 50%) is being challenged by the increasing consumption of calcium carbonate.

Note: the dominant varieties selected in different regions are different. In North America, the paper industry is mainly kaolin, in Europe, calcium carbonate, and in Asia, talc.

The content of papermaking filler is increasing year by year in the world, and with the development of medium alkaline papermaking process, calcium carbonate has become the most important papermaking filler. In 2010, calcium carbonate accounted for 73% of the consumption structure of paper filler.

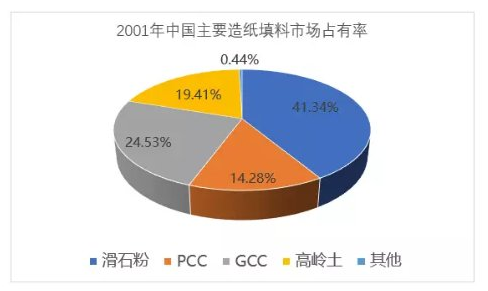

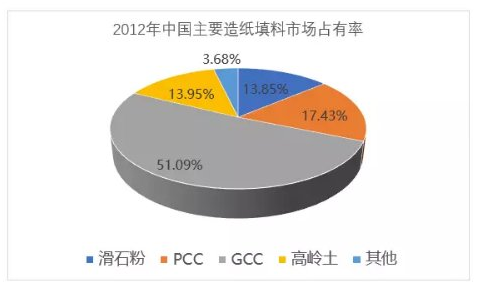

Before 2001, talcum powder was the main filler for papermaking in China. In 2001, talcum powder was still the most consumed paper filler (41.34%). With the strong rise of calcium carbonate, the consumption of calcium carbonate for papermaking in China exceeded that of talc for the first time in 2002. In the following ten years, the consumption of calcium carbonate, especially the heavy calcium carbonate, in the paper industry increased dramatically, with an average annual growth rate of more than 25%. In 2012, the market share of heavy calcium in the paper industry has reached 51%. In recent years, the annual growth rate of calcium carbonate has decreased significantly, and calcium carbonate has entered a slow growth period in the field of papermaking.

Data show that the growth of calcium carbonate is mainly based on calcium carbonate. In recent years, the annual growth rate of calcium carbonate has decreased significantly, and calcium carbonate has entered a slow growth period in the field of papermaking. However, with the rapid development of China's calcium carbonate industry and the progress of ultra-fine technology, the demand and consumption of submicron to nano calcium carbonate increase rapidly. It can be predicted that calcium carbonate will still occupy the dominant position in papermaking filler in the future, and with the progress of industry and technology, high-grade fillers other than calcium carbonate, talcum powder and kaolin, such as titanium dioxide, will be more and more used in papermaking industry.